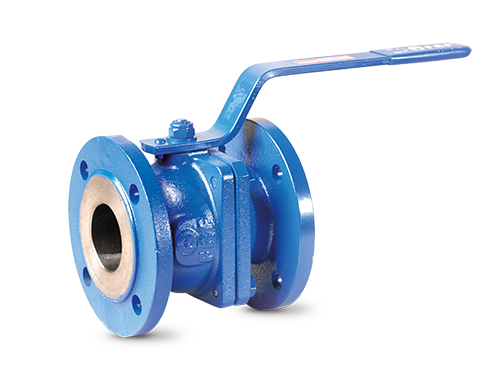

Flanged Ball Valve (2 Pieces)

Flanged ball valve is a type of valve used to control or stop the flow in a pipeline. The term “2 pieces” generally indicates that the valve body consists of two main parts. This type of valve typically includes a body and a cover.

The key features of the flanged ball valve with a 2-piece design may include:

Spherical Design: A sphere (ball) is present between the valve body and the cover. This sphere can be rotated to control the flow of the fluid.

Flanged Connections: The valve is mounted to the pipeline with flanged connections. Flanges securely attach the valve to the pipeline, ensuring tight sealing.

2-Piece Body: The valve body usually consists of two main parts. These parts often include the flanged connection points.

Fully Open and Fully Closed Positions: Ball valves are often used in fully open or fully closed positions. This allows the fluid to flow freely or come to a complete stop.

Durable Materials: The body and cover are typically made from durable materials, ensuring the valve’s longevity. Materials such as stainless steel, cast iron, or carbon steel are commonly used.

Various Sizes and Pressure Classes: Flanged ball valves are often available in various sizes and pressure classes, accommodating different application requirements.

These valves are commonly used in various applications such as industrial facilities, water systems, chemical plants, and power plants. Flanged ball valves are preferred for their easy installation, durability, and effective flow control.

Flanged Ball Valve (3 Pieces)

Flanged ball valve (3 pieces) is a type of valve used to control or stop the flow in a pipeline. The term “3 pieces” indicates that the valve consists of three main parts. These parts typically include the body, the middle section of the cover, and the cover. This design can facilitate the removal and maintenance of the valve or the replacement of valve components.

The key features of the flanged ball valve (3 pieces) design may include:

Spherical Design: A sphere (ball) is present between the valve body and the middle section of the cover. This sphere can be rotated to control the flow of the fluid.

Flanged Connections: The valve is mounted to the pipeline with flanged connections. Flanges securely attach the valve to the pipeline, ensuring tight sealing.

3-Piece Body: The valve body typically consists of three main parts: the upper cover, the middle section, and the lower cover. These parts are often connected to each other with screws or bolts.

Fully Open and Fully Closed Positions: Ball valves are often used in fully open or fully closed positions. This allows the fluid to flow freely or come to a complete stop.

Durable Materials: The body, the middle section of the cover, and the cover are usually made of durable materials, ensuring the valve’s longevity. Materials such as stainless steel, cast iron, or carbon steel are commonly used.

Various Sizes and Pressure Classes: Flanged ball valves are often available in various sizes and pressure classes, accommodating different application requirements.

These valves are commonly used in various applications such as industrial facilities, water systems, chemical plants, and power plants. Flanged ball valves are preferred for their easy installation, durability, and effective flow control. The three-piece design makes valve removal and maintenance processes more convenient and user-friendly.

Would you like to get detailed information about our products and services?

RVL Yangın

You can send us your Quote requests via the offer form.